Forced Labour Regulation: What It Means for Your Supply Chain

A new EU regulation on forced labour will take effect in 2027 and expand on existing rules under the CSDDD. Here’s what it’s all about – and what companies need to prepare for.

Key Takeaways

Starting December 14, 2027, products made using forced labour may no longer be imported, exported or sold within the EU. This applies across all industries, regardless of company size or turnover. Supply chain managers will need to take a closer look at their suppliers and strengthen their due diligence processes.

What is the Forced Labour Regulation?

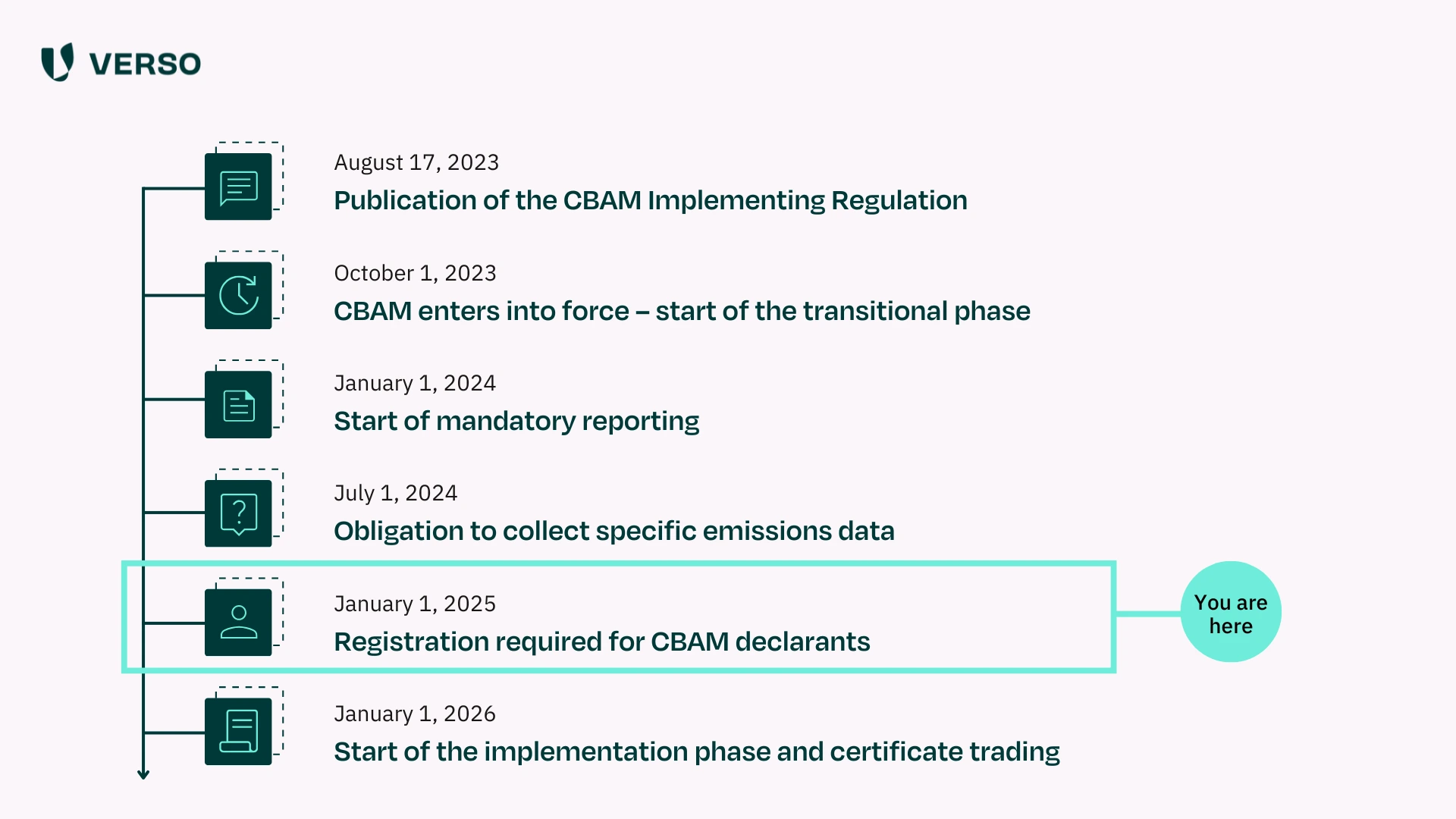

In late 2024, the EU adopted the “Regulation on prohibiting products made with forced labour on the Union market” – also known as the Forced Labour Regulation. It will apply from December 14, 2027.

Its goal is simple: Any product linked to forced labour must not enter or circulate within the EU market. This includes imports, exports and domestic sales.

Just like the EUDR and CBAM, the regulation takes a product-based approach. It doesn’t matter how big your company is or what sector you’re in – if a product in your supply chain involves forced labour, the regulation applies.

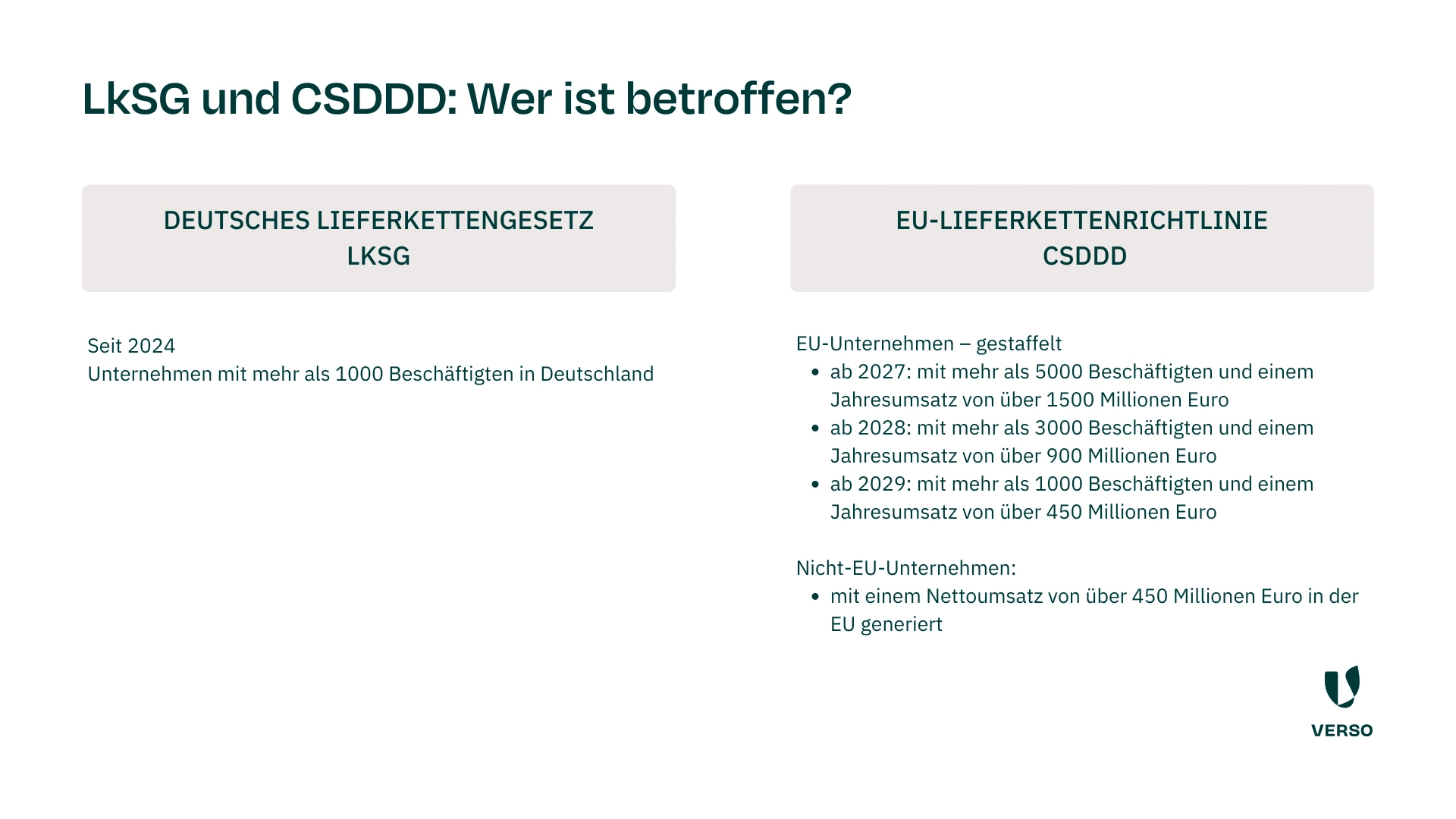

The new rules build on and complement existing human rights laws like the German Supply Chain Act (LkSG) and the upcoming CSDDD.

What Counts as “Forced Labour”?

The regulation uses the definition provided by the International Labour Organization (ILO):

“all work or service which is exacted from any person under the threat of a penalty and for which the person has not offered himself or herself voluntarily.”

The ILO lists several warning signs, including:

- Exploiting vulnerable people

- Deception

- Restricting workers’ freedom of movement

- Isolation

- Physical or sexual abuse

- Threats and intimidation

- Confiscating ID documents

- Withholding wages

- Debt bondage

- Poor or unsafe working and living conditions

- Excessive overtime

What Does This Mean for Supply Chain Managers?

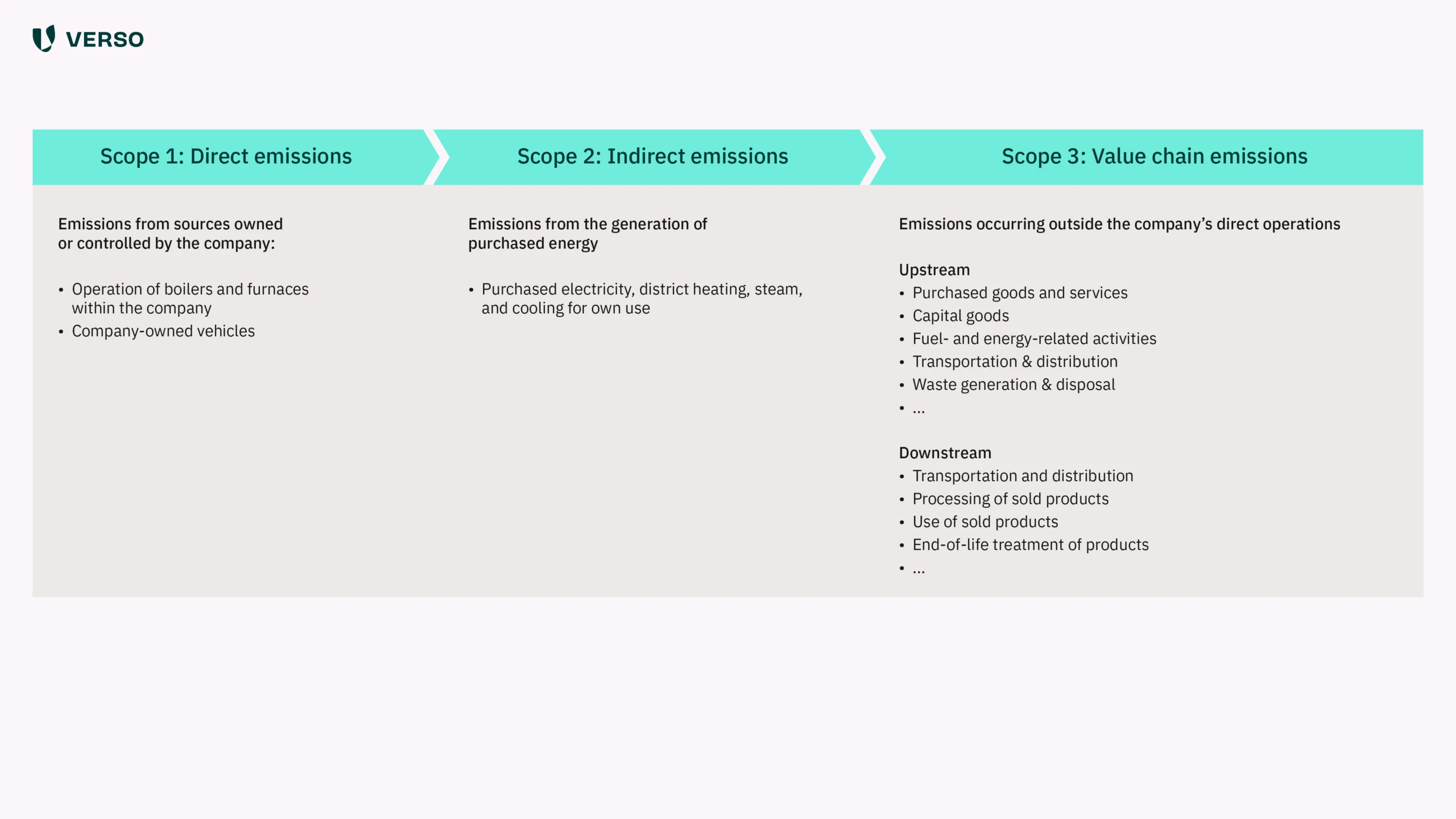

In short: You’ll need to expand your due diligence processes and include the ILO’s forced labour indicators in your risk assessments.

The Forced Labour Regulation is primarily addressed to national and EU authorities. These authorities are responsible for identifying potential risks and must provide guidance on high-risk regions as well as support services (see also: EU Council – Explanation of the Investigation Procedure). To support this, the EU will set up a dedicated “EU Forced Labour Single Portal.”

If authorities identify signs of forced labour in a company’s supply chain, further investigations will follow.

To comply with the new regulation and demonstrate that your supply chains are free from forced labour, your company will need:

- Supply chain transparency – Gain a clear overview of potentially high-risk products, suppliers and manufacturers.

- Active supplier management – Collaborate with your suppliers to eliminate forced labour risks in your supply chains.

- Enhanced due diligence processes – Build on the structures you already have in place for existing regulations. Resources such as the ILO Helpdesk for Business on International Labour Standards can support your efforts.

How Does the Forced Labour Regulation Differ from the CSDDD?

As a supply chain regulation, the CSDDD already includes human rights requirements and obliges companies to identify and address human rights risks in their supply chains. So why introduce a separate Forced Labour Regulation?

The key difference lies in scope and focus.

- Unlike the CSDDD, the Forced Labour Regulation applies across all sectors and is not limited to companies with a certain turnover or number of employees. This gives it a significantly broader reach.

- At the same time, it is much more specific: while the CSDDD addresses overall sustainability in supply chains, the Forced Labour Regulation focuses solely on forced labour.

- And while the CSDDD relies on penalties, liability claims and public disclosure of violations, the Forced Labour Regulation goes a step further – products linked to forced labour are categorically banned from the EU market.

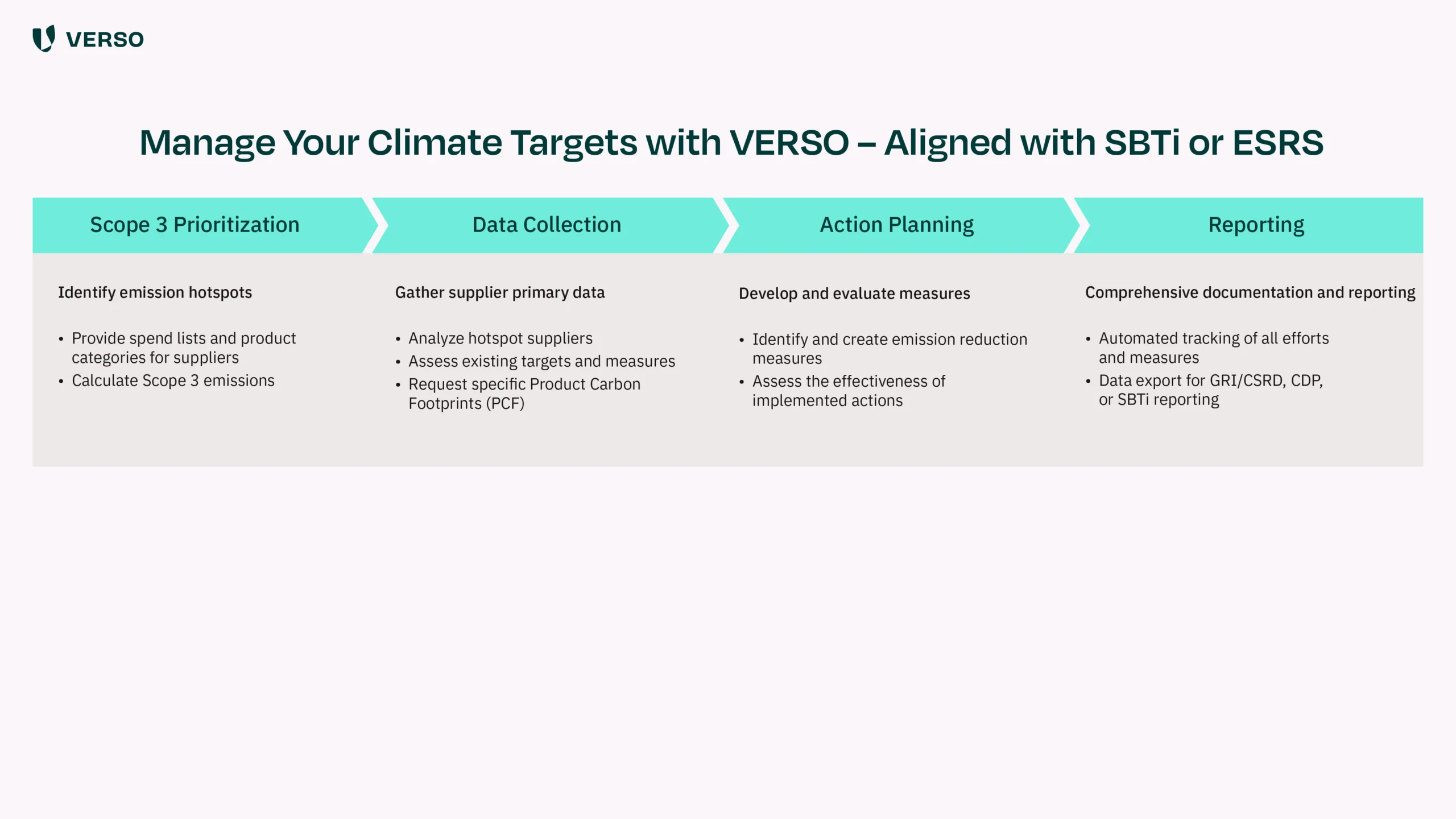

What VERSO Can Do to Help You Identify and Prevent Forced Labour

Since 2010, VERSO has supported SMEs in turning sustainability goals into real progress. With the VERSO Supply Chain Hub, you gain full visibility across your supplier network, assess risks, take action where it matters, and document your efforts reliably.

Feel free to reach out to us directly. We’d be happy to discuss how VERSO can help you identify and eliminate forced labour risks in your supply chain.

*This information is summarized editorial content and should not be considered legal advice. VERSO assumes no liability.