Earth Overshoot Day:

3 tips for sustainable resource management

Earth Overshoot Day marks the day on which we humans have used up all the natural resources we are entitled to for the year. Earth Overshoot Day shows us that we must take action! In this blog post, you will find lots of information about Earth Overshoot Day as well as three tips for more sustainable resource management in your company.

Let’s imagine that: At the beginning of August, we have already spent our entire annual salary.

We should now be planning our big summer vacation – but no, there’s not a single cent left.

From now on, we’ll have to live on credit and somehow get by until the end of the year.

Not a nice idea, is it?

The scary thing is: This is exactly how we are treating our planetary resources – and this is what Earth Overshoot Day stands for.

In 2024, Earth Overshoot Day falls on August 1.

All the natural resources that we humans are actually entitled to this year have been used up.

From this day onwards, we will be living at the expense of the future – for another 5 months.

A bitter day?

Absolutely, there’s no denying it.

But it doesn’t help to bury our heads in the sand.

Let’s use the day as a reminder: let’s act now and push Earth Overshoot Day as far back as possible!

Following the information about Earth Overshoot Day, this blog post therefore contains three tips on how you can make your company’s resource management more sustainable.

These simple measures, which every company can implement, actively contribute to environmental and climate protection.

Definition: What is Earth Overshoot Day?

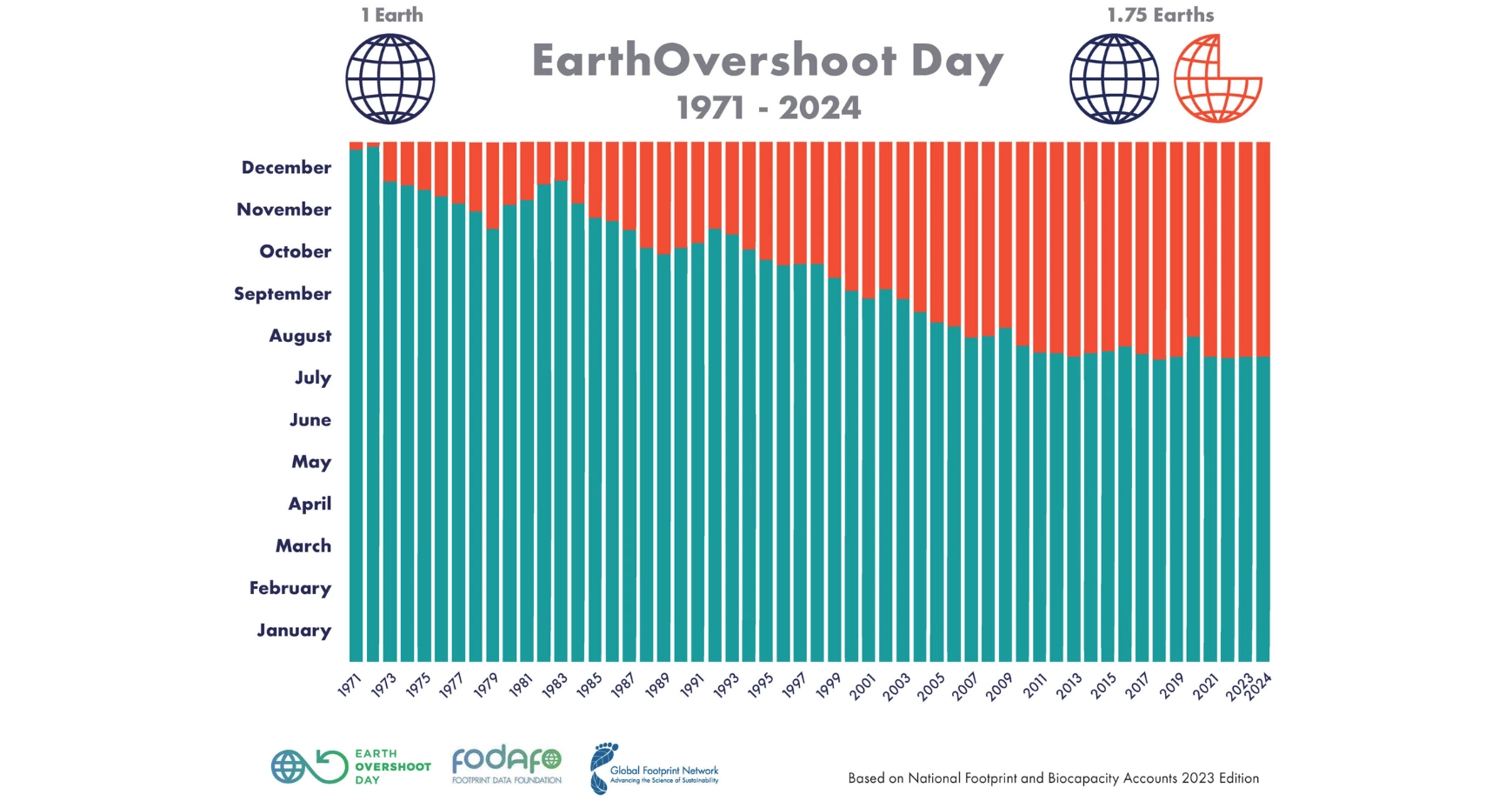

Earth Overshoot Day has been calculated since 1971.

In German, it is also known as Earth Overshoot Day or World Exhaustion Day.

It marks the date on which humanity’s demand for ecological resources and services in one year exceeds what the earth can regenerate in that year.

This is how the WWF describes it, for example.

The overshoot days are calculated globally and nationally – the total global consumption of resources is used or the consumption of a specific country is extrapolated to the global availability of resources.

The calculations for the overshoot days are based on the concept of the ecological footprint.

It describes the biologically productive area on earth that is necessary to enable a person’s lifestyle and standard of living.

In short, it documents how much nature we have and how much we need.

Earth Overshoot Day is calculated by the Footprint Data Foundation, York University and the Global Footprint Network.

Earth Overshoot Day earlier and earlier

It’s no big surprise: Earth Overshoot Day is always earlier, and it has steadily moved forward over the past 50 years.

Since the 2010s, however, it has settled around the beginning of August.

It all started in 1971: the first Earth Overshoot Day came as a worrying Christmas present under the Christmas tree, so to speak.

It fell on December 25, but at least we were still almost on target.

However, the consumption of resources continued to increase and so did Earth Overshoot Day.

As early as 1974, it moved to November, from 1987 to October and in 1999 it was in September for the first time.

Since 2005, Earth Overshoot Day has been in August and is steadily approaching July.

In 2018 and 2022, Earth Overshoot Day was already on August 1, the earliest date to date.

Each time it was a little later the following year.

In 2024, it will fall on August 1 for the third time.

The coronavirus pandemic and specifically the year 2020 represent a notable break in the statistics.

Global lockdowns and restrictions, the decline in production and transportation had a drastic impact on people and the economy.

But energy and resource consumption and CO2 emissions also fell significantly and the Earth Overshoot Day slipped back to August 16.

However, the effect did not last long and was no longer strongly felt the following year.

If you follow the development of Earth Overshoot Day closely, you will have noticed the fluctuations.

From time to time the day is later than in the previous year or it is adjusted retrospectively.

This can also be related to optimizations in resource consumption.

However, the reasons are usually more precise calculation methods and improved data sets.

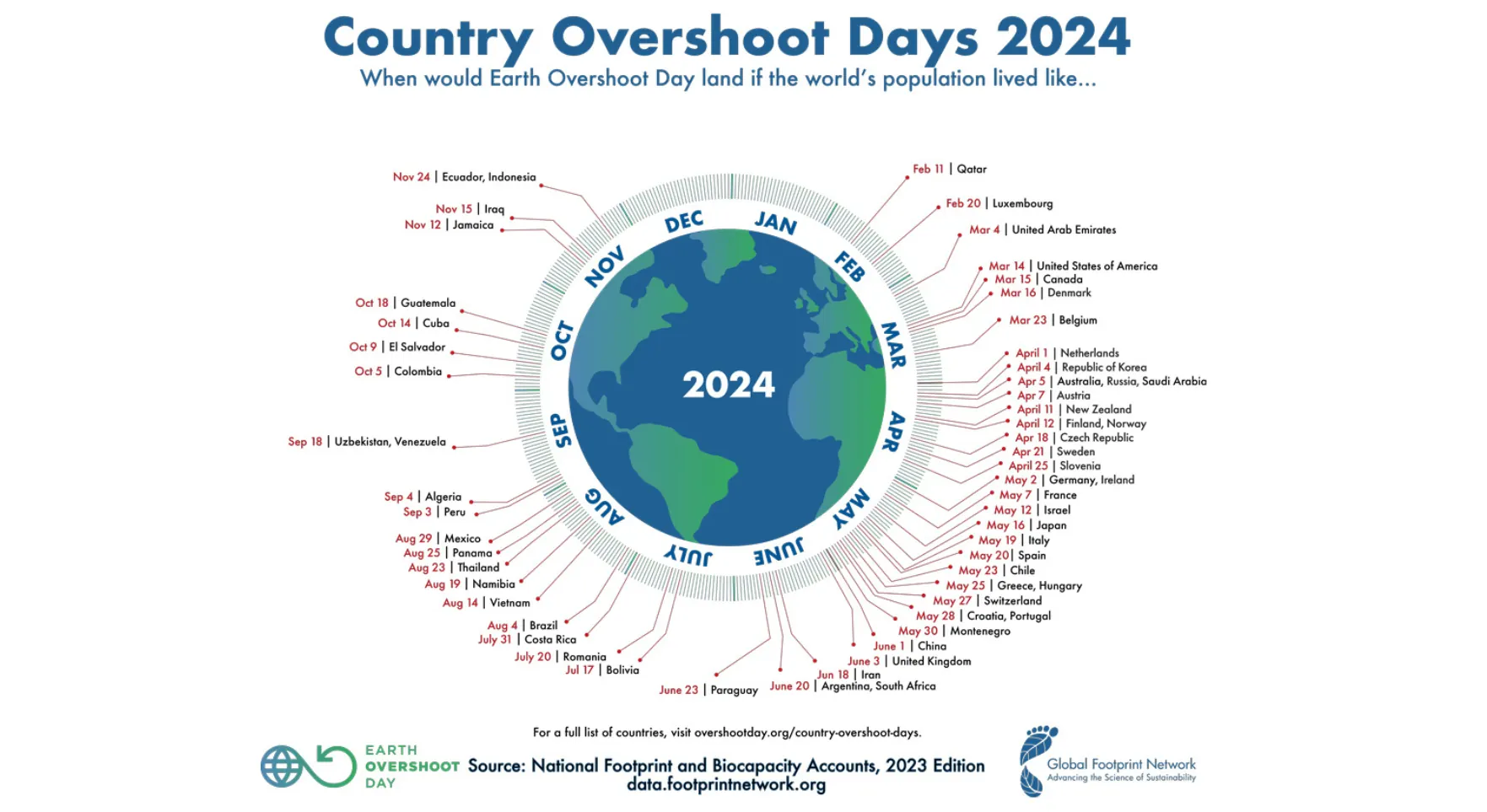

Overshoot Day for Germany

Calculated for Germany alone, Overshoot Day is even earlier.

In 2024, it already fell on May 2.

This means that if every country consumed resources like we do in Germany, everything the planet can offer and regenerate would already be used up by that day.

In other words, if everyone lived like we do, we would need three Earths.

Compared to previous years, not much has changed with regard to Germany’s Overshoot Day.

It is consistently at the beginning of May – except for the outlier in 2020 due to coronavirus.

So we haven’t got worse in Germany, but we haven’t really improved either.

However, it is also worth taking a look at other countries for comparison.

The three earliest Country Overshoot Days in 2024 were in:

- Qatar: February 11

- Luxembourg; February 20

- United Arab Emirates: March 4

The three countries for which the respective Country Overshoot Day was calculated for the latest date are:

- Guinea: December 27

- Moldova: December 28

- Kyrgyzstan: December 30

And to conclude the comparison, let’s take a look at three G12 countries:

- USA: March 14

- France: May 7

- China: June 1

What Earth Overshoot Day means for your company

Earth Overshoot Day is first and foremost a wake-up call to humanity.

The initiators want to show that our actions can lead to unpleasant consequences.

And these consequences will also be felt by companies, or are already being felt.

One example is extreme weather events such as droughts or floods, which are occurring more frequently and more intensively as a result of climate change.

They show how vulnerable global supply chains are.

The consequences are often crop failures, shortages of raw materials or blocked transport routes.

All of this is already leading to bottlenecks in supply and production – and the trend is currently increasing rather than decreasing.

3 tips for sustainable resource management in your company

Resource consumption affects us all.

Even as private individuals, we can make a difference.

The WWF lists various ways for end consumers to live more sustainably and thus push back the date of World Exhaustion Day.

“Buy green, consume less and eat less meat” is the succinct but effective recommendation for private individuals.

However, one of the biggest levers for saving resources worldwide is the economy.

Anyone who now thinks that sustainability is just something for a clear conscience or regulatory reporting obligations is mistaken: sustainable management brings business value, creates competitive advantages and strengthens the future viability and resilience of companies.

Many measures can save you money.

These three tips will help you get closer to sustainable resource management:

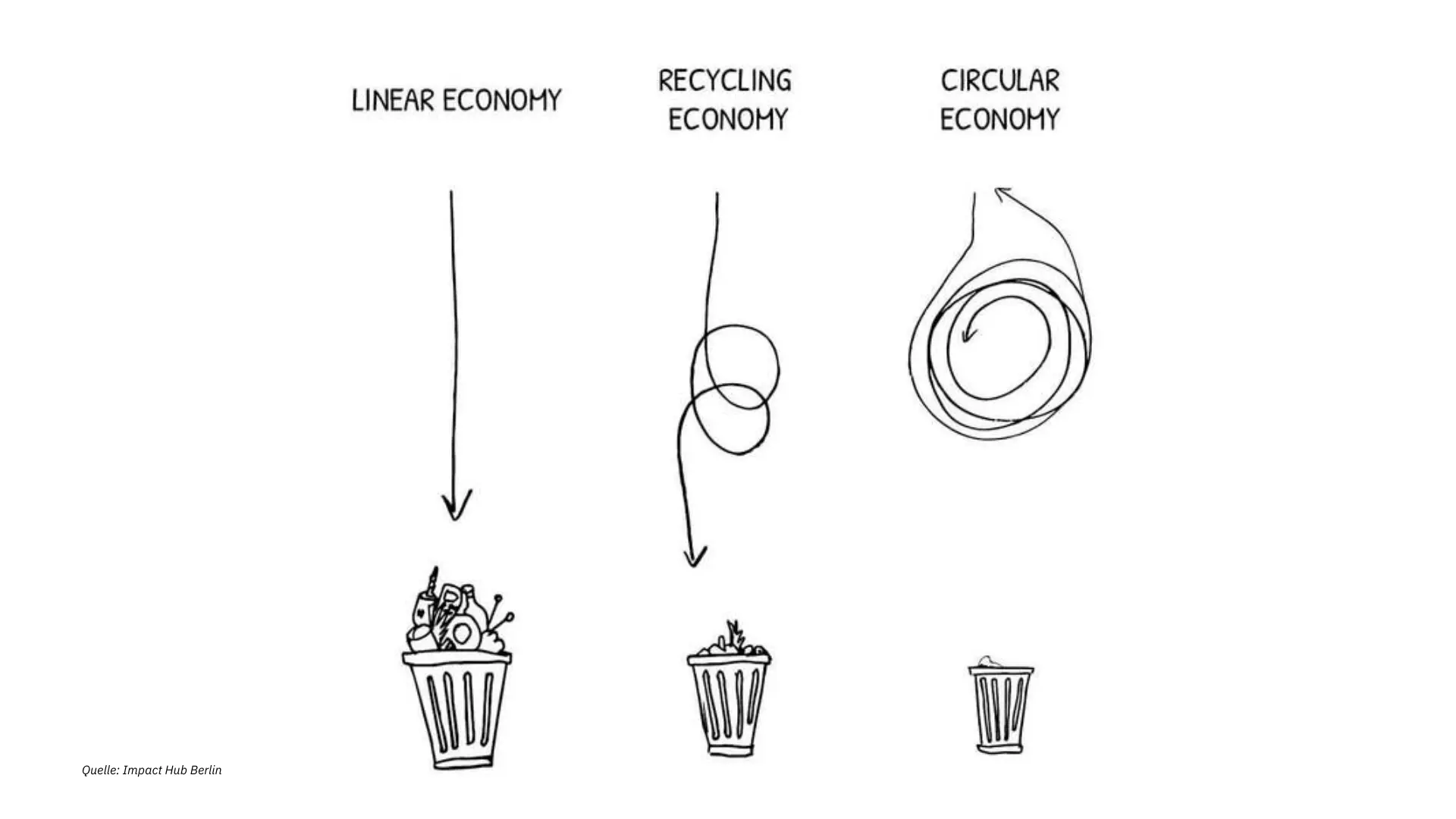

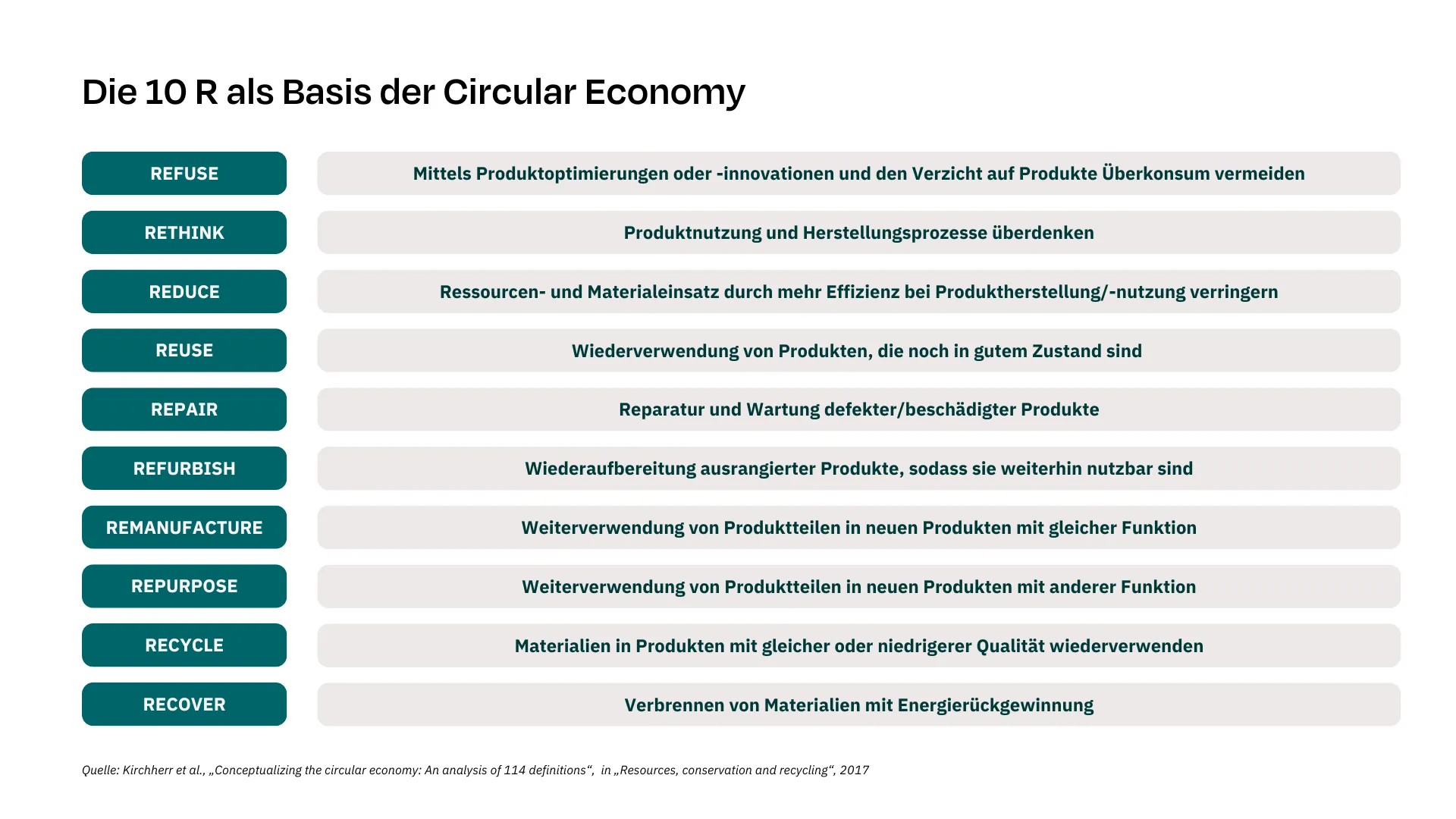

The three big Rs – Reduce, Reuse, Recycle

One of the most effective methods for establishing sustainable resource management in a company is the circular economy.

It starts with the big three Rs: Reduce, Reuse, Recycle.

It is about reducing the use of resources and materials, reusing products and reusing the materials from one product in another product.

One approach is an internal recycling process in which production waste is collected, processed and reused.

This can significantly reduce waste and thus the amount of raw materials required.

In addition, recycled or bio-based materials can be ordered from suppliers.

Resources can also be saved during shipping.

For example, packaging that can be reused.

But also in transport itself.

There are special pooling systems for pallet cages and Euro pallets – a reusable system for load carriers, so to speak.

Empty runs by truck should also be avoided.

But savings can also be made quite simply in the office.

For example, in water or energy consumption.

Refillable printer cartridges produce less waste.

Or you can switch completely to a paperless office.

Incidentally, the three big Rs are just the beginning: the circular economy goes a big step further and focuses on the 10 Rs. The concept and many other interesting facts about the circular economy can be found in this blog post “How the circular economy works and what it can achieve in Germany“.

Save energy and use it more efficiently

Energy is an important resource for every company – which is why it makes sense to start here.

The range of measures to save energy and use it efficiently is very broad.

It starts with obvious and simple steps:

- Use LED instead of halogen lamps

- Install motion detectors for the lighting

- Adjusting the brightness of screens downwards

- Use laptops instead of desktop computers

You should also take a systematic approach here – an energy management system in accordance with ISO 50001, for example, is helpful.

Although individual measures can lead to savings, they can also cause problems in other areas.

Therefore, look at the big picture and start looking for energy guzzlers.

Air conditioning, heating and ventilation often offer opportunities for optimization.

Important: Also check whether there is a state subsidy for the replacement.

Or have you ever thought about hosting your website?

With tools such as the Website Carbon Calculator, you can calculate the CO2 footprint of your company website in no time at all.

In the blog post “How to communicate your sustainability on your website“, we provide simple tips under point 6 on how to make your website more sustainable without any design or coding knowledge.

Another way to save energy: your company can become an electricity producer itself.

Photovoltaic systems are not only suitable for building roofs, but also for parking lots.

Not only do you generate green electricity and cover part of your energy requirements, you also create a source of shade.

You can also participate in local wind farms.

Sensitize and train employees

Employees are the key to a company’s success.

This applies not only to purely financial success, but also to the implementation of ESG initiatives.

It is therefore important to sensitize the entire team to sustainable action and train them accordingly.

This firmly anchors sustainability in the corporate culture.

During workshops, you should emphasize waste separation and avoidance and give tips on saving water and energy.

If everyone, or at least many people, adapt their behavior a little, a lot can be achieved.

One question that everyone should ask themselves, for example: Do I really need to print out this document or will it suffice in digital form?

One major lever is the transport sector.

Switch to public transport for business trips within Germany.

At the same time, your company can reward environmentally friendly behavior – for example with rental bikes or a subsidy for public transport.

Is your company doing enough in terms of sustainability?

Here’s how to find out

A sustainability report is a good measurement tool for companies in terms of ESG and implementation.

It allows you to determine the status quo and see your development over the years.

On this basis, you can develop or adapt measures and targets.

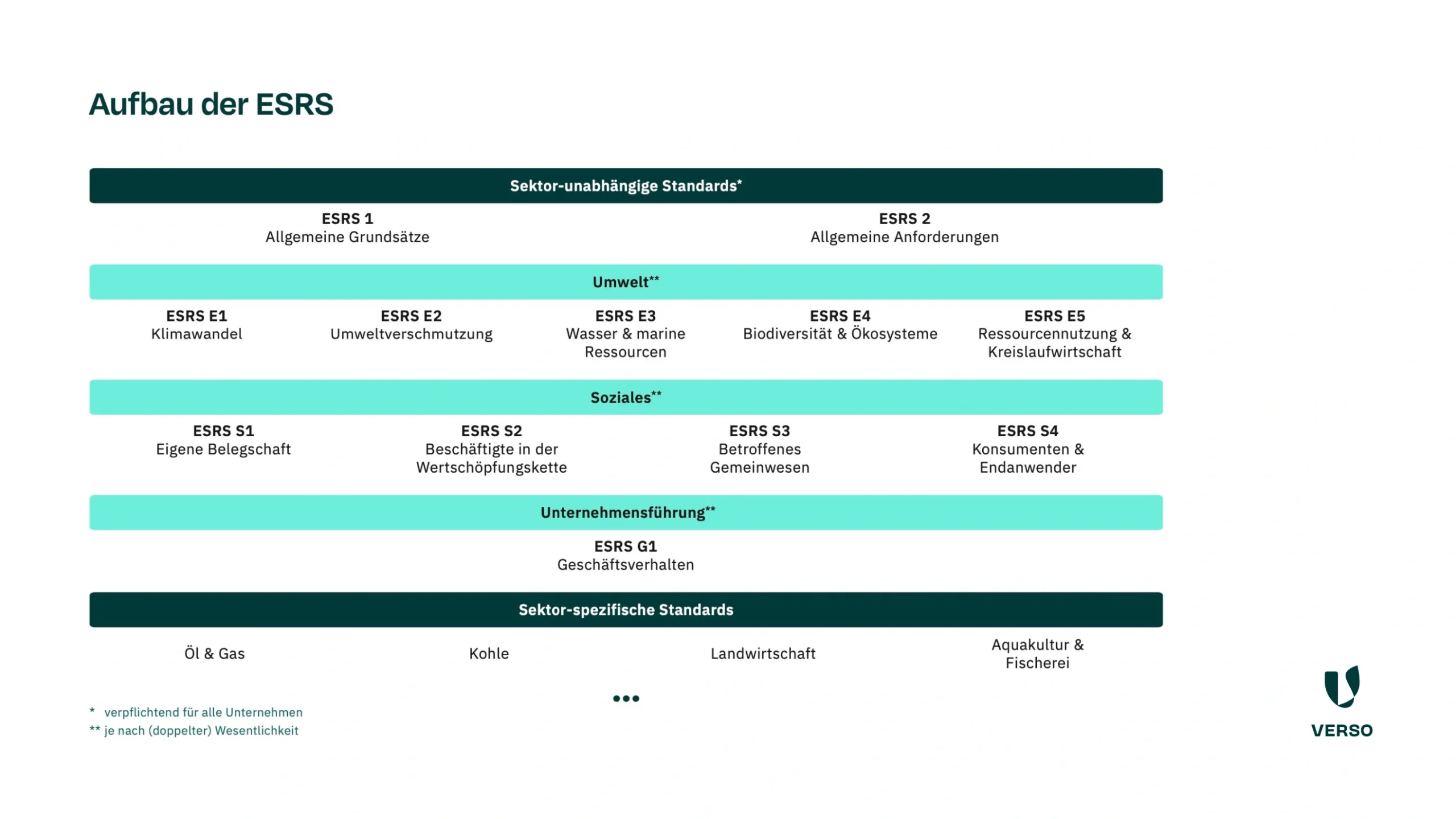

The CSRD reporting obligation may even mean that your company is obliged to prepare a sustainability report.

VERSO provides you with comprehensive support for this task.

With the VERSO ESG Hub, you can collect all relevant data and create a meaningful sustainability report.

The Climate Hub also calculates the corporate carbon footprint. And the VERSO Sustainability Experts will support you throughout the entire process. Would you like to acquire even more knowledge about ESG and sustainability yourself? Then it’s worth visiting our VERSO Academy. In the online courses, you and your colleagues can learn all about sustainability in the company – now with a brand new course for specialists and managers.

* This information is summarized editorial content and should not be construed as legal advice. VERSO accepts no liability.

Subscribe to our newsletter!

Sign up and receive regular news about:

- Pragmatic all-in-one solution for ESG reporting, climate and supply chain management

- Individual advice from the VERSO experts

- Developed with expertise from 12+ years of sustainability management

- Trusted by 250+ customers