ESG in der Lieferkette: 19+1 To-dos für den Einkauf

Anforderungen bis zum Horizont: Wo sollten Sie am besten anfangen, um ESG-Compliance entlang der Lieferkette zu schaffen und die vielen Chancen von ESG für Ihr Unternehmen zu realisieren? Dieser Beitrag zeigt’s – mit 19 To-dos und einem Bonustipp.

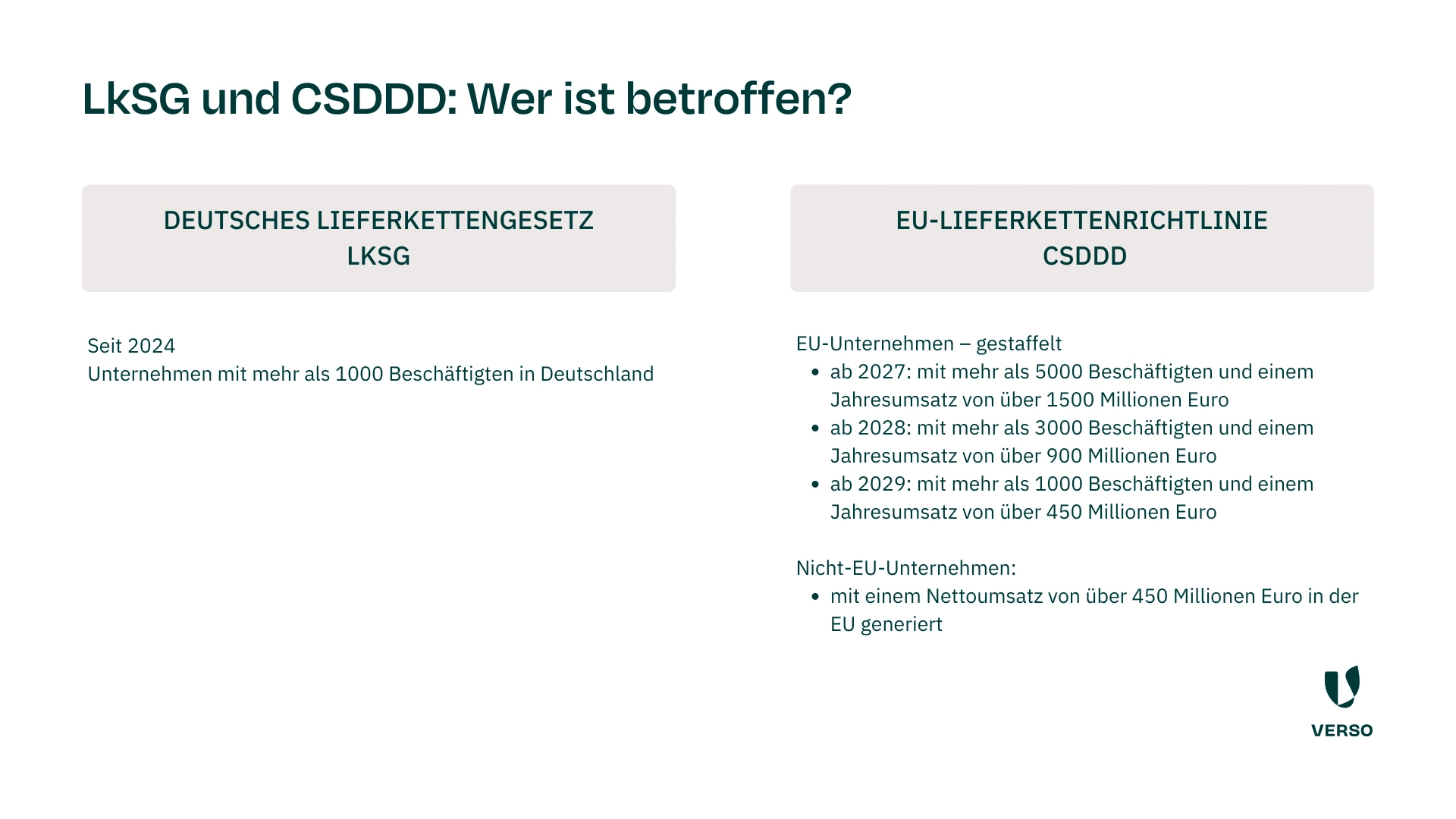

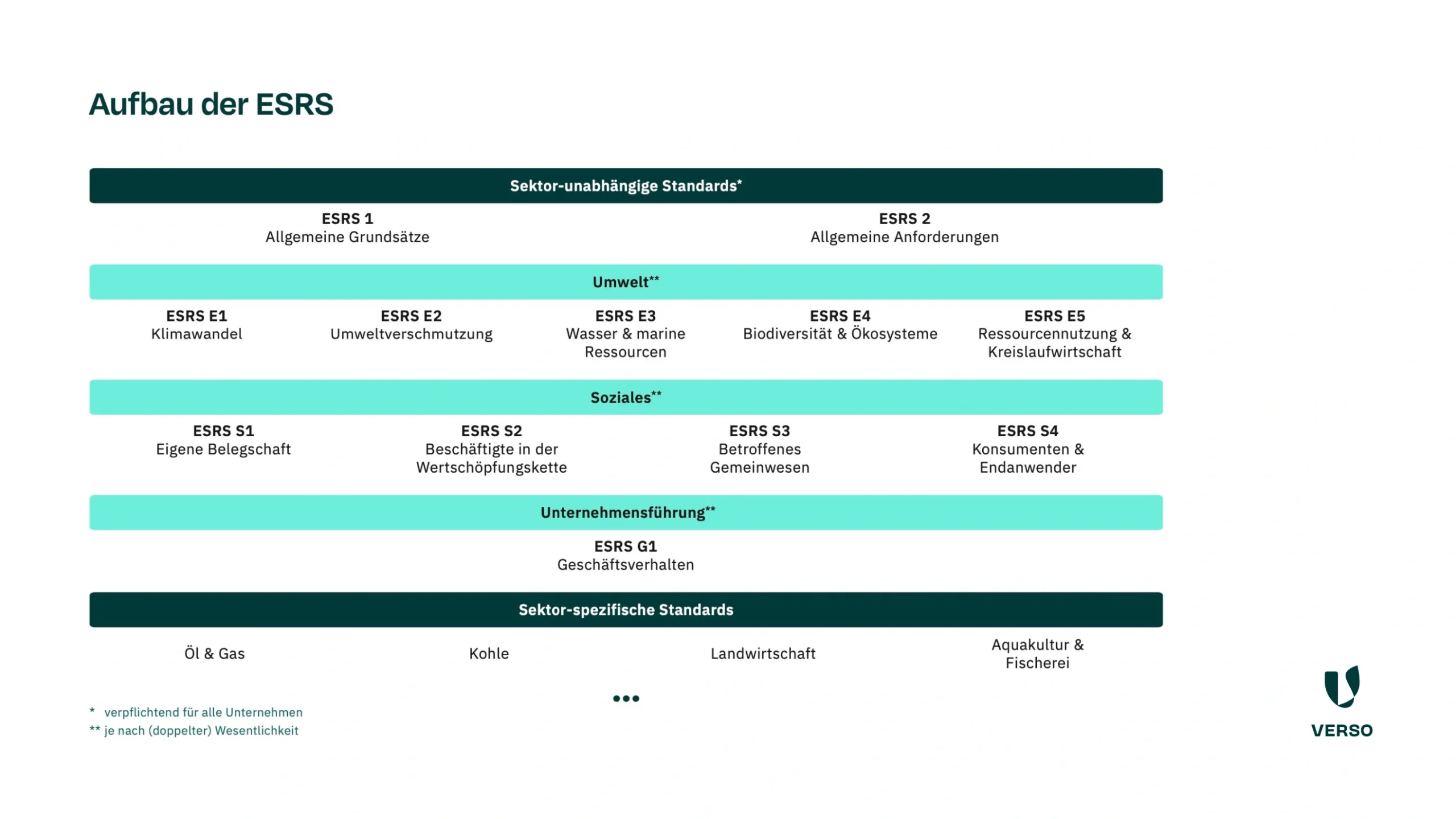

Für Einkaufs- und Supply-Chain-Verantwortliche bedeuten Regularien wie das LkSG, die CSDDD, die CSRD, die EUDR und der CBAM: mehr Dokumentationspflichten, höhere Transparenzanforderungen und steigender Druck auf Lieferanten.

Trotz aller Herausforderungen ist ESG-Compliance in der Lieferkette eine Chance, Risiken frühzeitig zu erkennen, Kosten zu senken und die eigene Marktposition zu stärken. Mit der richtigen Strategie wird Nachhaltigkeit vom Cost Center zum Profit Center.

Doch wo fangen Sie am besten an? Diese praxisnahe Checkliste mit 19 umsetzbaren To-dos und einem Bonustipp verschafft Klarheit.

Leiten Sie diesen Beitrag gern weiter, wenn er Ihnen weitergeholfen hat.

ESG-Regularien überblicken und priorisieren

1. Abgleichen, welche ESG-Regularien Ihre Lieferkette betreffen könnten

| Lieferketten-Regularien mit Anwendung in 2025 | Lieferketten-Regularien mit Anwendung nach 2025 |

|---|---|

| LkSG | Forced Labour Regulation |

| CSRD | CSDDD |

| EUDR | ESPR/Digitaler Produktpass |

| EU-Taxonomie | Right to Repair |

| CBAM | |

| EU-ETS | |

| Weitere Regularien wie Batterie-VO oder Kreislaufwirtschaftsgesetz |

2. Prüfen, welche Regularien für Ihr Unternehmen gelten und wann – einige Regularien (z.B. CSRD, CSDDD und EUDR) werden gestaffelt umgesetzt

3. Für die meisten Unternehmen sind aktuell vor allem CSRD, LkSG/CSDDD, CBAM und EUDR relevant

Zum Weiterlesen:

ESG-Daten in der Lieferkette erfassen und Transparenz erhöhen

4. Aktuelle Lieferanten-Stammdaten einholen und Ansprechpartner festlegen

5. Standardisierte ESG-Abfragen für Lieferanten nutzen, durch gezielte Audits überprüfen

6. Scope-3-Emissionen und Hotspots erfassen

7. Klimaziele für die Lieferkette festlegen, Klimastrategie implementieren

Zum Weiterlesen:

ESG-Risiken identifizieren und managen

8. Lieferanten nach menschenrechtlichen, umweltbezogenen und Klimarisiken überprüfen (abstrakte, konkrete und anlassbezogene Risikoanalyse)

9. Maßnahmen zur Risikoprävention etablieren und Abhilfemaßnahmen schaffen

10. Ganzheitliches, zukunftssicheres Managementsystem für Lieferketten-Risiken etablieren

Lieferantenmanagement für langfristige ESG-Compliance stärken

11. ESG-Kriterien in Lieferverträgen verankern, Code of Conduct kommunizieren

12. ESG-Reifegrad der Lieferanten ermitteln

13. Schulungen und Unterstützungen für Lieferanten anbieten, um ESG-Standards zu verbessern

14. ESG-Performance der Lieferanten regelmäßig prüfen

Zum Weiterlesen:

IT-Systeme prüfen und Datenverwaltung optimieren

15. Schnittstellenfähigkeit Ihrer IT-Systeme prüfen

16. Digitale ESG-Datenverwaltung einführen, um vollständige Transparenz und Kommunikation mit Lieferanten zu gewährleisten

ESG-Reporting abhaken und Compliance sicherstellen

17. Daten konsolidieren und Berichtsprozesse standardisieren

18. Regelmäßiges Reporting sicherstellen, dabei Synergien nutzen: Einige BAFA-Anforderungen (LkSG) überschneiden sich mit den ESRS (CSRD), EUDR- und CBAM-Daten und können für CSRD-Bericht weiterverwendet werden

19. Externe Prüfstellen (z.B. Wirtschaftsprüfer:innen) frühzeitig einbinden

Bonustipp: So gelingt ESG-Compliance in der Lieferkette mit weniger Aufwand

Zugegeben: Die ESG-Vorgaben für Lieferkettenverantwortliche sind anspruchsvoll. Aber mit der richtigen Strategie lassen sie sich effizient bewältigen. Nutzen Sie diese Checkliste als ersten Anhaltspunkt, um Ihre Lieferkette ESG-konform aufzustellen. Eine genauere Aufschlüsselung finden Sie in unserem Praxisleitfaden für nachhaltige Lieferketten.

Unser Bonus-Tipp: Der VERSO Supply Chain Hub schafft Transparenz und unterstützt Sie effizient bei der Umsetzung von LkSG, CSRD, CBAM und EUDR – automatisiert und rechtlich abgesichert.

* Bei diesen Informationen handelt es sich um redaktionell zusammengefassten Content, der nicht als Rechtsberatung zu verstehen ist. VERSO übernimmt keine Haftung.

Das könnte Sie auch interessieren:

Abonnieren Sie unseren Newsletter

Tragen Sie sich ein und erhalten Sie regelmäßig Neuigkeiten zu:

- Aktuellen ESG-Themen und Gesetzesänderungen

- Best Practices aus den Bereichen ESG und nachhaltige Lieferketten

- News zu VERSO

- Sustainability Events uvm.