PPWR: The moste important questions and answers for companies

The PPWR (Packaging and Packaging Waste Regulation) introduces comprehensive requirements for companies across the entire packaging value chain. In this article, we answer the key questions about the PPWR and outline which obligations will apply starting in 2026.

The PPWR (Packaging and Packaging Waste Regulation) – also known as the new EU Packaging Regulation – introduces comprehensive requirements for companies across the entire packaging value chain. It covers packaging design, recyclability, labeling, extended producer responsibility (EPR), and packaging waste reduction. Here, you will find the key questions about the PPWR and learn which obligations will apply starting in 2026.

1. What is the PPWR (Packaging and Packaging Waste Regulation)?

The PPWR (Packaging and Packaging Waste Regulation) is a key component of the European Green Deal. As a uniform, directly applicable framework, it replaces the previous Packaging Directive. The regulation aims to strengthen the circular economy across the EU, reduce packaging waste, increase recyclability and material efficiency, and harmonize existing rules throughout the EU.

2. When does the PPWR apply?

The PPWR entered into force on February 11, 2025. It will apply starting August 12, 2026, and will be rolled out in stages through 2040, with key milestones in 2028 and 2030.

3. Who is affected by the PPWR?

The PPWR applies to all packaging and packaged products placed on the EU market. Starting August 12, 2026, goods packaged in non-compliant packaging may no longer be marketed within the EU.

Exceptions and specific provisions apply to packaging for dangerous goods, medical devices, sensitive food contact materials, and innovative packaging, providing flexibility where safety or innovation considerations justify it.

The PPWR has an extremely broad scope. As a result, it affects a wide range of companies, including:

- Suppliers of packaging or packaging materials

- Manufacturers of packaging or packaged products

- Distributors, importers, and fulfillment service providers

- Brand owners placing packaged goods on the EU market

- Non-EU suppliers delivering products or packaging to the EU

The following sectors are particularly impacted:

- FMCG / fast-moving consumer goods (food, beverages, personal care)

- Retail, e-commerce, and online marketplaces

- Packaging manufacturing

- Logistics, fulfillment, and transport packaging

- Textiles, apparel, and footwear (packaging-related aspects)

- Hospitality, food service, and take-away (HORECA)

4. Which roles does the PPWR define?

The PPWR establishes clear obligations for each economic operator along the supply chain and generally distinguishes between producers, importers, distributors, and suppliers.

Manufacturer

A natural or legal person that manufactures packaging or a packaged product, or has packaging or a packaged product designed or manufactured under its own name or trademark. (This includes packaging manufacturers as well as companies such as Amazon.)

Supplier

Any natural or legal person that supplies packaging or packaging materials to a producer.

Importer

Any natural or legal person established in the EU that places packaging from a non-EU country on the EU market.

Distributor: Any natural or legal person in the supply chain—other than the producer or importer—that makes packaging or packaged products available on the market.

5. What does the PPWR role “Producer” mean, and how does it differ from “Manufacturer”?

Under the PPWR, “Producer” refers to any producer, importer, or distributor—regardless of where they are established—that places packaging or packaged products on the market in a Member State for the first time. Producers assume additional obligations, including extended producer responsibility (EPR) for collection and recycling. The term should not be confused with “Manufacturer.” The Manufacturer is one of the roles covered under the broader term “Producer.” There is also potential for confusion in German terminology: in the regulatory context, “Hersteller” refers to the entity responsible for first placing packaging on the market, while “Erzeuger” refers to the entity that manufactures packaging or packaged products.

It is important to understand that within a packaging value chain, there is only one Manufacturer, but there may be multiple Producers. Whether a company qualifies as a Producer must be assessed separately for each Member State, depending on who places the packaging or packaged product on the market first.

6. What does “Extended Producer Responsibility” mean in the context of the PPWR?

A key element of the PPWR is the principle of Extended Producer Responsibility (EPR). EPR compliance requires producers to take responsibility not only for manufacturing and distributing their products, but also for managing the end-of-life treatment of the associated packaging.

For example, online retailers based in Germany that sell goods to end customers in Austria must appoint an authorized representative in Austria, register in the national producer register, and pay the applicable fees there.

7. How will EPR fees change under the PPWR?

Starting 18 months after publication of the EU criteria, EPR fees will be modulated based on environmental performance. This means the fees will be structured according to how sustainable the packaging is. For example, lower fees will apply to packaging with higher recyclability.

8. What obligations does the PPWR introduce for companies?

The PPWR introduces extensive sustainability and information requirements for companies across the entire value chain. These obligations cover packaging design and material selection as well as documentation, labeling, traceability, and reporting.

Key obligations—depending on the company’s role—include:

1. Compliance & chemical safety (from 2026)

- Compliance with limits for substances of concern (e.g., PFAS, heavy metals), especially for food contact materials

- Conducting conformity assessment procedures

- Preparing technical documentation

- Issuing an EU Declaration of Conformity (DoC)

2. Labeling & transparency (from 2028 onward)

- Harmonized labeling on material composition

- Information on compostability, take-back schemes, or deposit return systems

- Labeling of reusable packaging

- Providing information to authorities and market surveillance bodies

- Registration and compliance within the framework of extended producer responsibility (EPR)

3. Design and sustainability requirements (phased in through 2040)

- Minimizing weight, volume, and empty space (maximum 50% for transport and e-commerce packaging from 2030)

- Ban on certain single-use plastic packaging formats

- Recyclability requirements (at least 70% from 2030, 80% from 2038)

- Design for recycling to enable material recovery

- Minimum recycled content in plastic packaging (10–35% from 2030, up to 65% by 2040)

- Compliance with binding reuse targets

- Industrial-scale recyclability (from 2035)

4. Specific requirements for certain packaging types

- Mandatory compostability for specific applications (e.g., tea bags or fruit labels)

- Reuse options in take-away settings

- Allowing customers to use their own containers

9. What specific requirements apply starting in 2026?

If you are the Manufacturer of the packaging or packaged products:

- You must carry out a conformity assessment procedure and prepare the technical documentation and EU Declaration of Conformity.

- You may not use substances of concern in packaging materials (e.g., PFAS, heavy metals).

- You are subject to general labeling requirements.

If you purchase packaging or packaged products downstream from a Manufacturer or from your suppliers, you are subject to due diligence obligations. These include, among other things, verifying compliance of the packaging and ensuring that labeling requirements have been properly fulfilled.

10. What requirements apply regarding empty space and overpackaging?

Starting January 1, 2030, grouped, transport, and e-commerce packaging may contain no more than 50% empty space. Filling material is considered empty space. Packaging weight and volume must be reduced to what is strictly necessary, and cosmetic practices such as double walls or false bottoms are prohibited, with only limited exceptions.

11. What impact does the PPWR have on the supply chain?

The PPWR increases data requirements for suppliers and packaging manufacturers across the entire packaging supply chain. It requires clear allocation of responsibilities within the packaging value chain and leads to greater coordination efforts between procurement, sustainability, quality management, and suppliers. At the same time, risks increase due to incomplete or outdated supplier data. As a result, transparency and a digital, readily accessible data foundation become increasingly important.

12. How should companies prepare for the PPWR now?

Companies should establish transparency at an early stage regarding affected packaging and suppliers, review existing data and supporting documentation, and define clear processes for data collection and maintenance. It is also crucial to involve suppliers in a timely manner and build digital structures to ensure scalable and audit-proof compliance.

Our approach:

- Assess PPWR readiness across the supply chain

- Raise supplier awareness and provide training – without additional workload

- Collect and analyze packaging data in an automated way

- Optional advisory services for strategic and operational implementation

13. How does the PPWR relate to other ESG requirements?

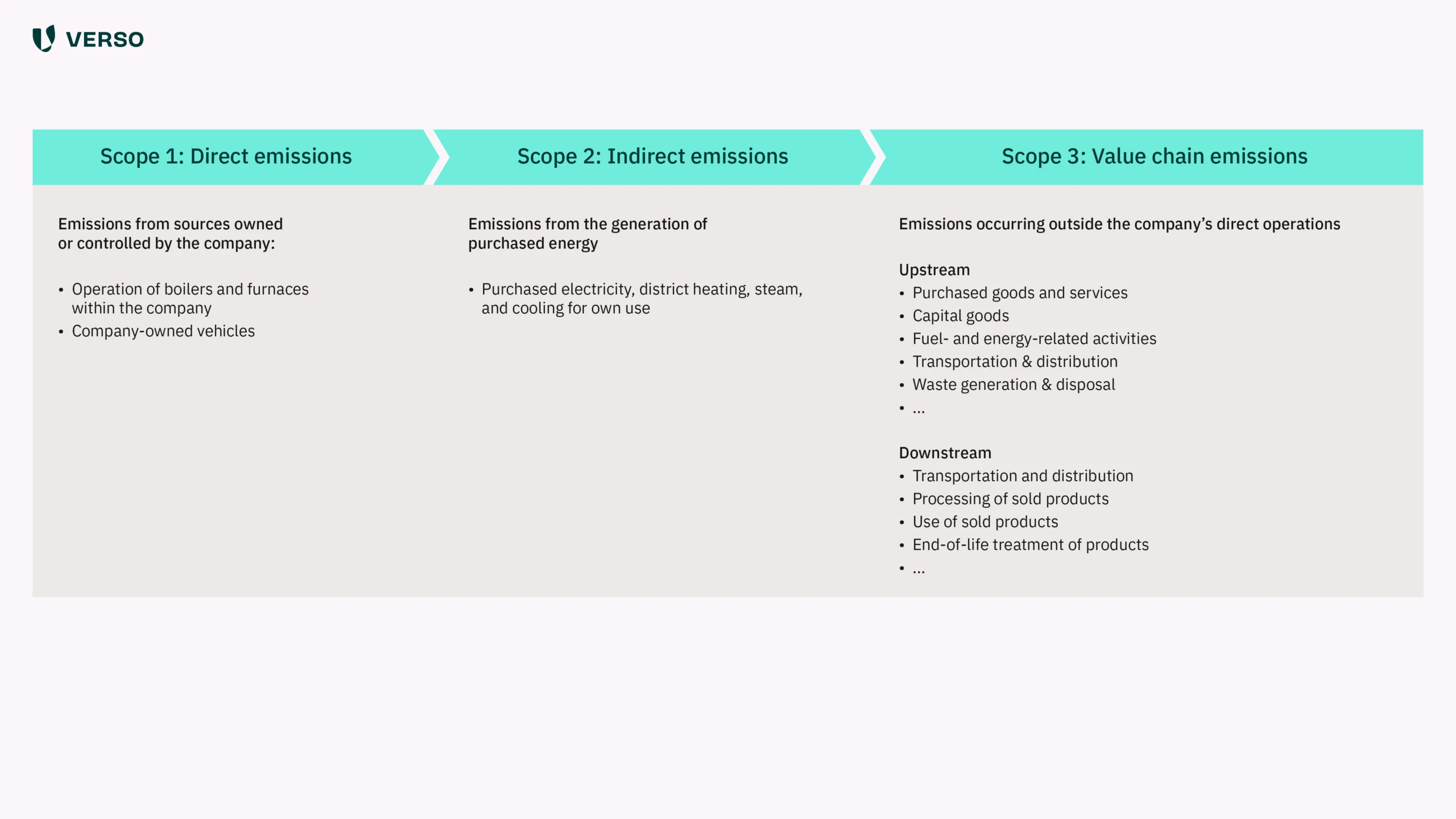

Supply chain decarbonization

The PPWR promotes recyclable and material-efficient packaging, reducing the use of virgin raw materials and energy-intensive production steps. This creates a direct lever for lowering Scope 3 emissions.

REACH / RoHS

The PPWR builds on existing chemicals regulations and further specifies substance requirements for packaging, for example by setting limits for PFAS and heavy metals to systematically reduce environmental and health risks.

ESRS E5 – Circular Economy

The PPWR operationalizes ESRS E5 requirements by defining binding criteria for recyclability, material composition, and recoverability of packaging. This enables robust and comparable ESG metrics.

EUDR – Traceability

Similar to the EUDR, the PPWR requires transparent traceability of materials and suppliers to demonstrate regulatory compliance across the supply chain.

Digital Product Passport (DPP)

The PPWR provides key data points for the Digital Product Passport, particularly regarding material composition, substances, recyclability, and compliance. It thus lays the foundation for digital, standardized transparency at product and packaging level.

14. Why should companies implement the PPWR early?

Companies should implement the PPWR at an early stage to reduce compliance, liability, and market access risks, while avoiding last-minute implementation challenges and supply chain bottlenecks. Acting now enables companies to build robust data structures instead of relying on manual, ad hoc solutions and strengthens their positioning toward customers, retailers, and authorities. At the same time, the PPWR can serve as a lever for more efficient and sustainable packaging strategies. Early action also ensures sufficient time for necessary adjustments in research and development, including planning, testing, and scaling.

15. What penalties apply in case of PPWR violations?

In Germany, missing EU Declarations of Conformity, technical documentation, registrations, licensing obligations, or incorrect information may result in fines of up to €200,000. In addition, sales bans may be imposed. Specific penalties for individual PPWR obligations will be further defined through additional legal acts.

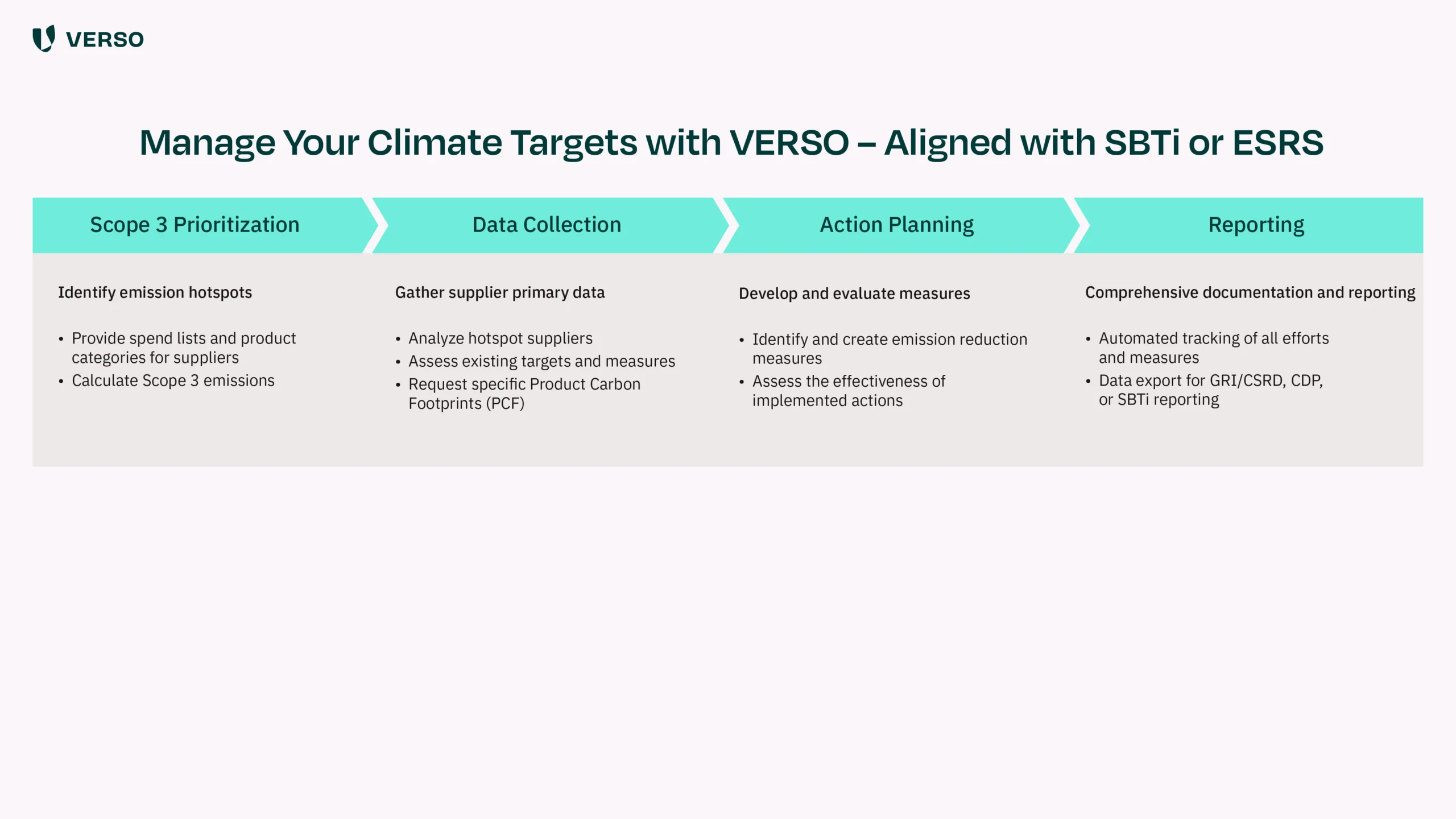

Implement PPWR with ease

Starting in 2026, PPWR compliance will become an operational reality—manual Excel spreadsheets will no longer be sufficient. With VERSO, you can digitize data collection, supplier communication, and documentation management in one central platform.

Want to understand your specific obligations? Take the PPWR Check. In just three minutes and a few clicks, you will see what applies to your company—and receive a practical checklist to help you get started.

* This information is summarized editorial content and should not be construed as legal advice. VERSO accepts no liability.

This might be also interesting for you:

Subscribe to our newsletter!

Sign up and receive regular news about:

- Current ESG topics and legislative changes

- Individual advice from the VERSO experts

- News about VERSO

- Sustainability Events and more